PCB boards are fabricated through several processes that conclude cutting, pretreatment, creating inner layer circuity, laminating the layers together, drilling holes, creating the top and bottom layer circuity, surface finishes, assembly prep, inspection, and test. The most difficult step is to create the required tracks on the board and remove the unwanted copper via a chemical etching process.

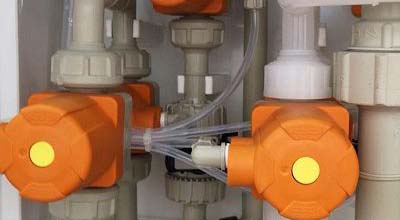

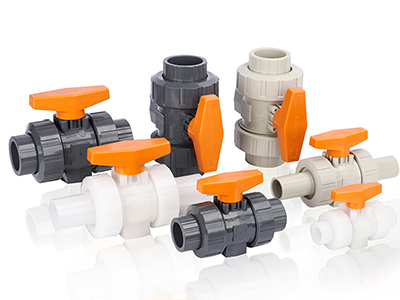

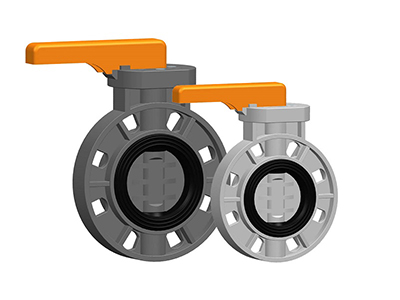

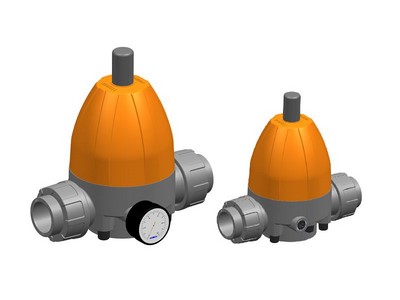

This process involves various corrosive chemicals which have strong permeability and are easy to crystalize. The traditional valves can not meet the application needs of the chemicals transportation, feed, and discharge either with too high cost or too short lifespan. KOSCN MV300, MV302 plastic diaphragm valves and PS700 pressure sensors can solve these problems due to excellent durability and reliability. Our valves provide perfect solutions to plumbing system in integrated circuit manufacturing industry with below strengths:

First, KOSCN plastic valves provide a broad range of models to choose from to cope with different chemical solvents. Second, unique valve design enables to perfectly handle chemical permeation or crystallization. Third, our plastic valves are provided to customers with the highest quality, the most economic price-performance ratio and the shortest lead time.