As a professional manufacturer of plastic valves, pneumatic actuators, and piping systems, KOSCN has strong capabilities of product design and mold making. Our injection molds are self-developed and our mold making workshop is equipped with CNC milling machines, CNC lathes, grinding machines, electrical discharge machines and other equipment to ensure the continuous innovation and stable manufacturing of molds.

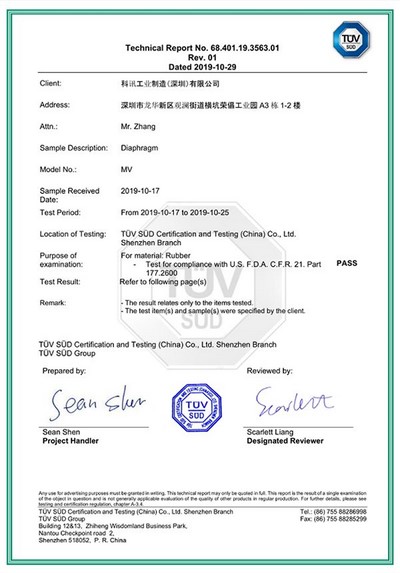

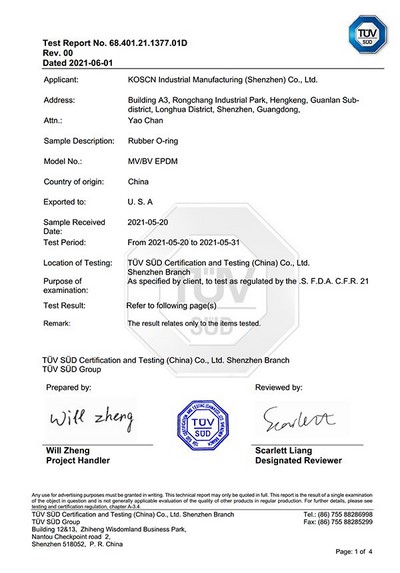

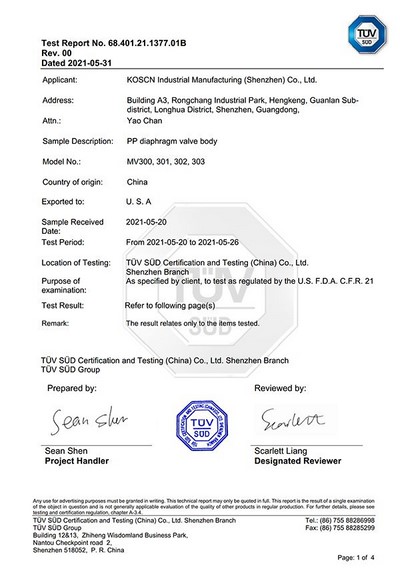

As the below table shows, all our raw materials are from branded suppliers to ensure the chemical resistance and heat resistance of valves and piping systems.

- PP

- PVDF

- EPDM

- EPM

- PTFE

- BOREALIS, BOROUGE

- SOLVAY

- DOW

- DUPONT

- DAIKIN

After molding, a fatigue test is conducted to ensure the performance stability.

KOSCN has a reliable supply chain for injection molding and our partners have rich experience and strong strengths in PVC, PP, PVDF, PFA injection molding, which are equipped with different injection molding machines from KRAUEEMAFFEI, HAITIAN or other famous brands. We provide high-quality raw materials and standard molds to our partners and our QC engineers will stay on-site to manage the product appearance, size, and quality.

Machining process is performed by our dedicated technicians who have over 20 years of experience in precision machinery manufacturing and are equipped with 4-aixs and 5-axis machining centers, CNC lathes, milling machines, wire EDM, CMM, OGP, CCD, injection molding machines and inspection equipment.

We carry out sampling inspection and in-process quality inspection to control the quality of assembly. Product standardization is achieved by employing auto or semi-auto equipment and setting technical parameters.

Our automatic assembly line includes:

Automatic seal ring assembly equipment

Automatic cylinder tightening equipment

Automatic cylinder screwdriving tool

Automatic part-turn actuator assembly equipment

Semi-auto valve seat assembly machine

Automatic airtightness inspection machine

Now, our production capacity of plastic valves has reached 10,000 pieces per month due to industrial leading assembly efficiency, standardization, and yield.

KOSCN has auto airtightness testers for MV, BV, PV, and other series of industrial plastic valves. All of them must pass the switch condition inspection and airtightness test.

We also have fatigue testing machines to inspect the diaphragm work life, assembly torque, spring torque to guarantee reliable and consistent product quality.